Product Description

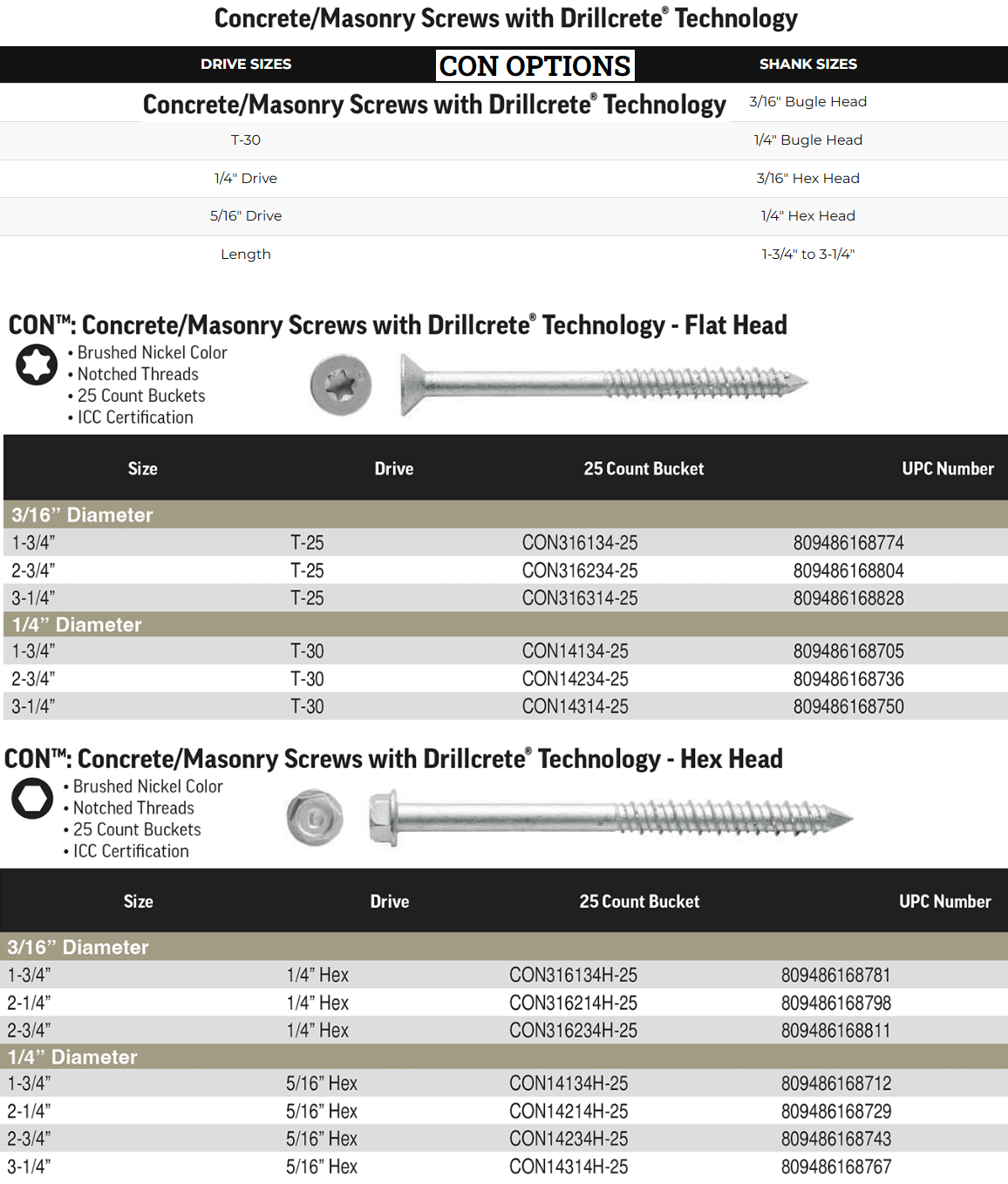

Big Timber CON Concrete/Masonry Screws Flat Head

• Brushed Nickel Color

• Notched Threads

• 100 Count Buckets

• Drill Bit Included

BENEFITS & FEATURES:

Unique Corrosion-resistant brushed nickel finish

Notched high/low thread design for easy installation - Unique qualities of the hi-lo thread specifications help minimize the amount of material displaced as the screw is driven into the material for superior holding power

Head Styles:- Bugle head with star drive recess- Hex Head • Great alternative to wedge anchors and plugs

Available in 3/16" and 1/4" diameter

Lengths 1-3/4" – 3-1/4"

Concrete/Masonry Screw with Drillcrete Technology backed by certified independent testing ( ESR-4420 and ESR-4421)

International Building Code and International Residential Code Compliant

ACQ Compatible

Optimal performance for light/medium duty applications in:- Concrete - Masonry block - Brick materials - Wood base materials

COMMON USES INCLUDE:

Numerous wood-to-concrete and steel-to-concrete applications

Used to anchor materials to concrete, cinder block, and brick such as:- Wood- Metal - Plastic a. Shelving brackets b. HVAC strapping c. Sill plates d. Furring strips e. Post bases f. Baluster posts g. Door thresholds h. Door frames NOTE: Always follow lumber manufacturer’s recommendations.

Use a Variable Speed Drill to drive the screws after the pilot hole has been drilled with a Hammer Drill

The proper depth of the pilot hole is dependent upon the material being fastened to the concrete.

Pilot holes for concrete screws should be at least 1/4 in. deeper than the screw will penetrate to allow a little extra space for dust accumulation from the hammer drilling process

Keep constant pressure on the screw and run the drill at slow to medium speed, Heavy-duty drills work best because they can maintain a steady slow speed

Drive the anchor in one steady and continuous motion until fully seated at the proper embedment.

Driving at high speeds may result in fastener failure