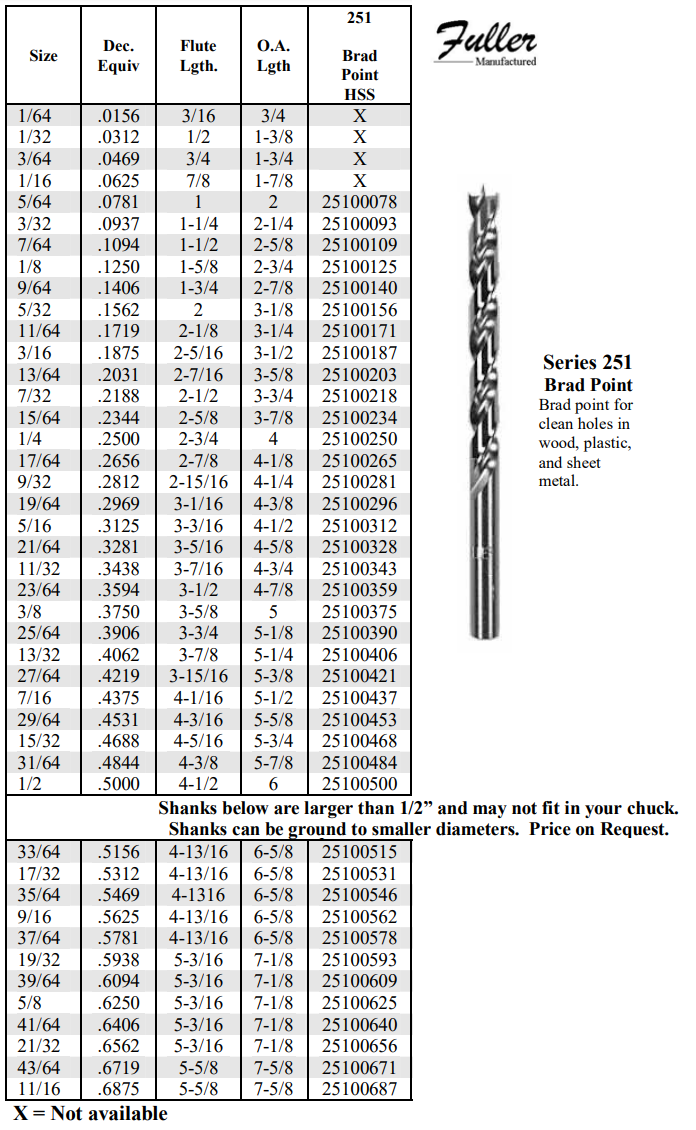

Product Description

A Brad Point Drill should provide the cleanest, straightest, and most accurately sized hole in wood of any reasonably priced tool

on the market today. The brad in the center of the point allows accurate positioning when starting a hole even if the hole is not 90

degrees from the surface. The outlining spurs sheer the wood grain and leave a clean edge around the opening of the hole

eliminating the need for sanding. The spurs continue to sheer the wood while drilling and produce an accurately sized hole. In

most woods, the spurs also help to produce a cleaner edge when drilling through the backside of the wood.

W. L. Fuller, Inc. has been manufacturing High Speed Steel Brad Point Drills for over 40 years. We have worked with thousands

of customers to produce Brad Point Drills that satisfy their needs. We stock Brad Point Drills in every size including Wire

Gauge, Letter Sizes, Metric Sizes and longer or shorter lengths. If there is a need for a size not covered by these, we can take

a standard size and grind and/or cut it to a needed special size. We use industrial quality High Speed Steel domestic drills

designed to cut metal and rework them to cut wood. The result is a Brad Point Drill made to metalworking tolerances with

cutting edges that long outlasts standard woodworking tools.

There are basically two types of brad point designs we use. One works best in hardwoods and the other works best in softwoods.

Brad Point Drills that are specifically designed for softwood produce too much heat and are hard to push in hardwoods. Although

Brad Point Drills specifically designed to cut hardwood will cut softwood, the aggressive cutting edges have a tendency to lift the

weak grains of the softwood resulting in a ragged edge around the opening of the hole. All of the Brad Point Drills we

manufacture and show in our catalog are specifically designed for hard wood and work fine for most applications.